Click through our offerings to see what ROTEX products we carry. Looking for parts or machine servicing? We do that too!

Call us at 630-924-1208 with any questions or use the link below to send us a message.

Can’t find what you’re looking for? Message us! We have a wide variety of Rotex products available.

- ROTEX INDUSTRIAL SCREENERS

- ULTREX SANITARY SEPERATORS

- APEX INDUSTRIAL SEPARATORS

- MEGATEX XD | MINERAL SEPARATOR AND SCREENING

- RTX360 CIRCULAR VIBRATORY SCREENER

- MEGATEX GRAIN CLEANER

- HI CLINE FERTILIZER SCREENERS

- PLASTIC PELLET SCREENER

- DIRECT DRIVE FEEDER

- GRADEX® 2000 PARTICLE-SIZE ANALYZERS

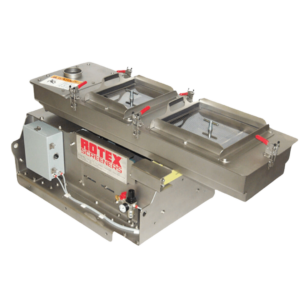

Rotex Industrial Screener

Meet the machine that launched an industry. Precise. Rugged. Versatile. Rotex®

FEATURES

Compensating Clamps

Patented adjustable clamps ensure uniform sealing of cover and screen decks.

Automatically Tensioned Screens

Patented quick-snap tension clips allow for even tensioning across the entire screen.

Customizable

Ask your Mills Winfield representative how we can fully customize your machine inlets/outlets and add liners, decks, aspiration and more.

Positive Screen Cleaning

Mesh cleaning balls keep screen openings clear, maintaining efficiency and capacity of your Rotex screener.

BENEFITS

Eliminates Screen Blinding

Through the use of Rotex’s mesh cleaning balls and Gyratory Reciprocating Motion, material blinding is virtually nonexistent.

Consistent Screen Tension

The screen is automatically tensioned with each new installation through the use of our unique screen-attachment method.

Longevity and Durability

Rotex screener drives are designed for long-term, trouble-free service with minimal maintenance.

Increased Screening Performance

All Rotex screener machines deliver greater efficiencies, superior particle accuracies and higher yields.

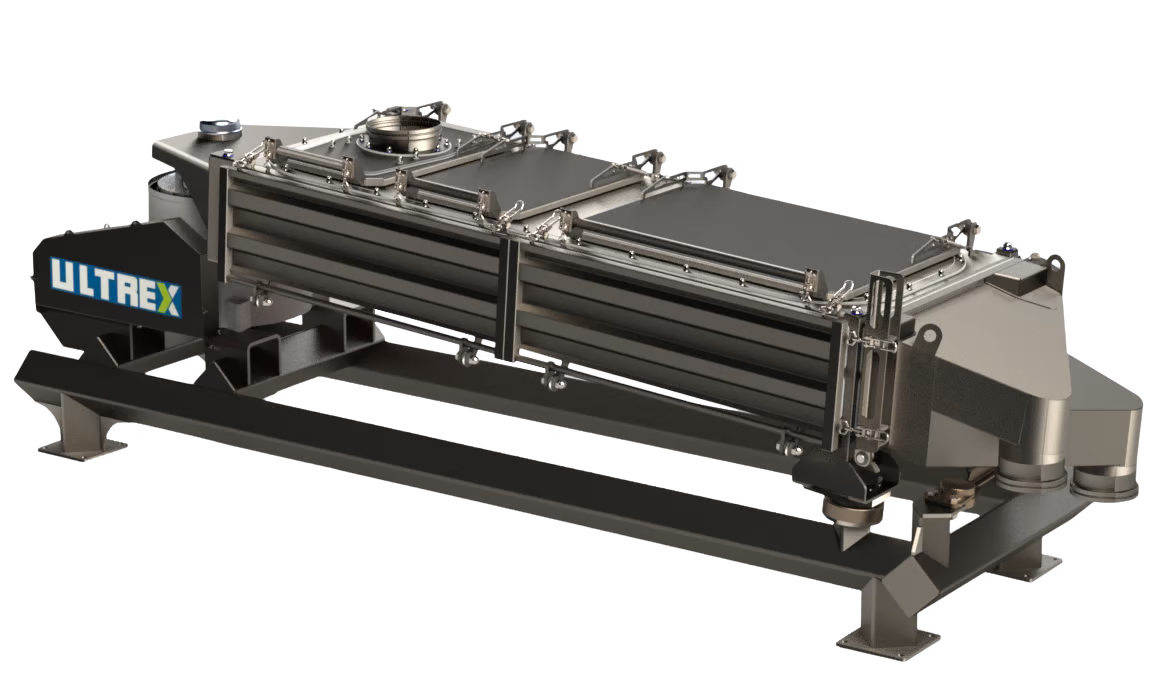

ULTREX™ SANITARY SEPARATORS

Sanitary, Ergonomic, and Efficient; the Ultimate Package.

The ULTREX™ industrial screener gives precise separations for food applications due to its ergonomic features and sanitary design. The ULTREX is USDA, EHEDG, and FSMA compliant for applications with the strictest sanitary requirements. Realize your highest standards with ULTREX.

FEATURES

Sanitary Separations

Engineered to be compliant with USDA, EHEDG, and FSMA requirements.

Toolless Ball Tray

Minimizes downtime for ball tray installation / removal and can be completed by a single operator.

Full Access Inside Screener

Washdown Capable

BENEFITS

USDA, EHEDG and FSMA Compliant Design

Product contact surfaces in the ULTREX are in compliance with recommended sanitary and hygienic standards.

Single Operator Maintenance

The ULTREX full view top cover panels and side access doors allow one operator to inspect and/or change a screen panel in minutes.

More Uptime, More Profit

Easy inspection and maintenance results in reduced screening costs and increased productivity.

Proven Screening Performance

The ULTREX gyratory-reciprocating motion delivers on-spec product at higher yields than competitive vibratory motions.

Longevity and Durability

Rotex drives are designed for long-term, trouble-free service with minimal maintenance required.

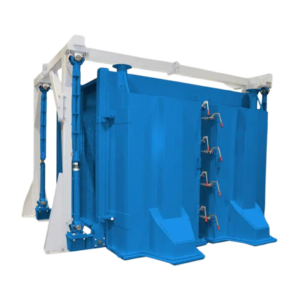

APEX INDUSTRIAL SEPARATORS

Maximum efficiency. Minimal downtime.

The APEX™ industrial screener provides extremely precise separations due to its Gyratory Reciprocating Motion and sleek ergonomic design. It enables one-person inspections and maintenance. Increase plant safety while decreasing downtime with APEX.

FEATURES

Pre-Tensioned Screen Panels

Each panel is individually tensioned and sealed; one panel provides nine or 12 square feet of screen area.

Side Access Doors

Tail-End Discharge Chute

Toolless Cams

BENEFITS

Quick Screen Changes

Side access doors combined with pre-tensioned screen panels allow a single operator to change the entire machine in minutes.

More Uptime, More Profit

Easy single-operator inspection and maintenance results in increased processing uptime, reduced screening costs and the ability to produce more quality product.

Increased Screening Performance

When compared to standard separators, all Rotex machines deliver greater efficiencies, superior particle accuracies and higher yields.

Longevity and Durability

Rotex drives are designed for long-term, trouble-free service with minimal maintenance required.

Customizable

Ask your Rotex representative how we can fully customize your machine inlets/outlets and add liners, decks, aspiration and more.

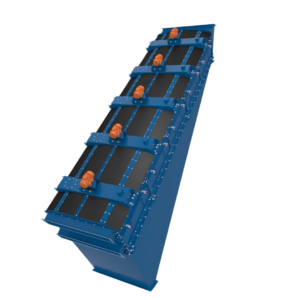

MEGATEX XD | MINERAL SEPARATOR AND SCREENING MACHINE

The highest capacities in a single unit.

Screen high-volume applications with extremely accurate separations using The Rotex Minerals Separator™/MEGATEX XD™. Every multilevel mineral separator features unique stacked designs for smaller footprints and was engineered to withstand the harshest conditions.

FEATURES

Accessible External Drive

Engineered to be compliant with USDA, EHEDG, and FSMA requirements.

Quick-Release Handle

Easily Replaceable Seals

Brush Connections and Sliding Inlet

BENEFITS

Reduced Downtime

The combination of quick-access clamps, external drives, and no flexible connections reduces downtime by making maintenance on the mineral separator easier.

Consistent Screen Tension

Through the use of our unique screen-attachment method, the screen is automatically tensioned with each new screen installation.

Eliminates Product Leakage

Each fraction is fully contained within the mineral separator through the use of our patented Cam Lift-Rail and customized internal seals.

Independent Screen Access

The stacked, multiple-deck, tray-access design allows individual screen access, which eliminates the need to remove all decks. A single deck screen change can be completed in 10 minutes, and all 12 decks within two hours.

Longevity and Durability

Rotex drives are designed for long-term, dependable service with minimal maintenance. In addition, 500 to 1,000 pounds of abrasion-resistant liners ensure your mineral separator will withstand any application.

RTX360 CIRCULAR VIBRATORY SCREENER

Unrivaled Performance and Expertise in a Compact and Economical Design

RTX360 Circular Screener delivers high-level Rotex performance while introducing vibratory motion within a compact footprint. The RTX360 is a highly competitive solution among circular vibratory screeners and separators.

FEATURES

Compact Design

Accessible Drive

Customizable Options

Quick Release Clamping

BENEFITS

Optimum Performance

The adjustable nature of the RTX360 Circular Vibratory Screeners allows for greater screening performance which results in higher efficiency.

Quick Screen Changes

Pre-tensioned panels allow 1-2 operators to change the entire machine within minutes.

Longevity and Durability

Designed for long-term, trouble-free service with minimal maintenance required.

Increased Performance and Expertise

Rotex’s expertise and product line options deliver greater efficiencies and solutions for any screening requirements.

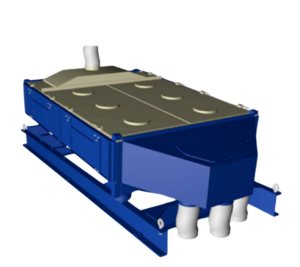

MEGATEX GRAIN CLEANER

Engineered for the grain industry.

The MEGATEX Grain Cleaner™ processes high volumes of agricultural materials that would overwhelm a conventional grain cleaner. It features aspiration doors and abrasion-resistant liners. Reduce your capital expenses with one machine that does it all — the MEGATEX Grain Cleaner.

FEATURES

Easily Accessible Screens

Quick-Release Handle

Abrasion-Resistant Liners

Coarse Scalping Turret

SPECIFICATIONS

MEGATEX Grain Cleaners come in three series ranging from 120 square feet all the way to 360 square feet. The tremendous screen area in a single unit allows the MEGATEX high capacity Grain Cleaner to achieve capacities up to 50,000 BPH.

HOW IT WORKS

Wide-Screen Design

When handling higher capacities, the depth of the material passing over the screen on conventional screeners increases. Increased bed depth diminishes the screener’s ability to stratify material, which is essential to effective screening. Expansion of the total screen area is key to increased screener capacity — but only if the area is increased properly. All screen area is not equally productive. Increased screen width expands capacity more effectively than increased screen length. MEGATEX grain screeners handle increased capacity and maintain screening accuracy by utilizing screen surfaces that are wider rather than longer. Using a two-bank, multilevel screen deck arrangement, MEGATEX grain screeners present 40 feet and 50 feet (12 meters and 15 meters) of width, respectively. This width serves to keep bed depths low, so screening accuracy and efficiency are maintained at high capacities.

Long-Stroke, Gyratory Motion

The force level created by the long-stroke (up to 7.5 centimeter), low-frequency drive serves two important functions. First, the motion effectively spreads the material across the full width of the distribution panel. This achieves proportional feeding to each of the screen levels inside the machine and eliminates the need for multiple process feed points. Second, the long stroke and low frequency produce effective ball-mesh cleaning to control blinding, providing long-term, uninterrupted operation. Screening units employing shorter strokes or higher frequency drives cannot match these two functions of the MEGATEX high capacity grain cleaner. Thus their screening effectiveness is poor, resulting in product loss or poor product quality.

HI CLINE FERTILIZER SCREENERS

High-frequency fertilizer screening.

Designed in collaboration with phosphatic fertilizer experts, the Hi Cline™ employs high-frequency vibration to rapidly separate DAP/MAP materials. Available in one- and two-deck models, the Rotex Hi Cline is the ideal solution for high-frequency fertilizer screening.

FEATURES

Ergonomic Design

Two-Year Warranty

Maintenance Ports

Screen Tension Control

BENEFITS

Large Product Range

The Hi Cline offers models from 60 to 150 square feet (5.6 to 13.9 square meters) of screen area in both single-deck and double-deck configurations.

Reduced Maintenance

Rubber covers allow quick and easy access to the top deck, bottom deck and large side doors, resulting in faster screen inspections and cleaning.

Built for Longevity

The Hi Cline screener carries a two-year warranty on the rugged vibrating motors, which have low energy-consumption rates.

PLASTIC PELLET SCREENER

Speed, accuracy and simplicity.

The competitively priced Plastic Pellet Screener™ accurately removes off-size material with a quick and easy setup between batches. The machine can be floor-mounted, stand-elevated or wheeled, while accurately screening and grading plastic. Rotex’s gyratory reciprocating motion sets the Plastic Pellet Screener apart from other plastic separators.

FEATURES

Toolless Access

Double-Pass Capability

Ergonomic Design

Pneumatic Tappers

BENEFITS

High Efficiency

Through the use of Gyratory Reciprocating Motion, screening efficiency is increased by removal of the longs without the loss of on-spec plastic pellets.

Superior Blinding Control

Mesh cleaning balls are eliminated through the use of pneumatic tappers. This results in less vertical motion on the pellets and further reduces the probability of longs diving through to the product fraction.

Cleanability

Lightweight parts easily handled by a single operator allow for easy disassembly during product changeovers.

Reduced Headroom

A lower silhouette than most other screening equipment allows for installation as low as 27 inches (68 centimeters).

Portable

An option is available for casters with kick-down legs.

Installation

Our plastic separators can be floor-mounted, stand-elevated, or on wheels. The low silhouette enables installation at a height as low as 27 inches (68 centimeters).

ROTEX DIRECT DRIVE FEEDER

Scalping and de-dusting in bulk.

The cost-effective Direct Drive Feeder™ (and conveyor) meets all the process requirements of bulk handling industries and can be configured horizontally or inclined to fit your exact floor space.

FEATURES

Customizable Design

Adjustable Drives

Enclosures

Screens

BENEFITS

Customizable Motion

The utilization of contra-rotating electromechanical motors imparts both an upward and forward stroke to the main feeder body. The angle of the motors determines the preference toward either lift or conveying.

Multiple Mounting Options

Various installation options include Rosta, barrel or suspension-style mounts. Safety straps are fitted where relevant.

Engineered Installations

Rotex can provide either an open type or fully enclosed type interface with or without a rod gate isolation system for hopper bottom installations.

GRADEX® 2000 PARTICLE-SIZE ANALYZERS

Tighter control over quality metrics.

The Gradex® 2000 allows you to analyze products on a more frequent and timely basis while eliminating operator error and bias. It combines reliable particle-size analysis with extremely low maintenance. It also comes with the Gradex 2000 Service Agreement, which is a two-year service contract that protects your particle analysis equipment against potential costly damage and unnecessary downtime.

FEATURES

Standard Test Sieves

Auto Feed Option

Automates Sieve Analysis

Customized Data Reports

BENEFITS

Eliminates Human Variance

Automated brushing and weighing results in a consistent standardized method that won’t differ or shift with personnel changes.

Increased Quality Control

More frequent and automated tests result in faster recognition of off-spec production.

Electronic Reporting

Automatically transfer the particle size analyzer results to a computer with customizable report formats.