Click through our offerings to see what Coperion K-Tron products we carry. Looking for parts or machine servicing? We do that too!

Call us at 630-924-1208 with any questions or use the link below to send us a message.

- Feeders

- Rotary Valves

- Diverter Valves

- Discharge Valves & Samplers

- Blower Packages

- Filters & Separators

- Vacuum Sequencing Receivers

- Controls

Industrial Drying Technologies For A Wide Variety Of Applications

PRODUCT LIST BELOW

Smart Feeding Solutions

No two process applications are the same, and Coperion K-Tron offers the widest range of feeding solutions in the industry. From screw feeders to vibratory feeders, bulk solids pumps, weigh belts, liquid feeders and flow meters, all feeders are offered in a variety of configurations, which can be combined to create an optimal solution for any application.

Areas of Application

We offer highly accurate solutions for handling a wide range of ingredients. Paper or plastic? Food or pharmaceuticals? Whatever the industry, we supply the feeders at the core of your manufacturing process. Our feeders can be found wherever bulk materials are processed, for a wide variety of applications. From chocolate chips to fiberglass, floodable powders to plastic pellets and waxy liquids, Coperion K-Tron offers the right feeder for any material.

Most feeders are available in either standard finish or special finishes with higher polish levels and ground welds for applications in the food industry, for example. A special line of screw and vibratory feeders has been developed specifically for the strict hygiene requirements of applications in the pharmaceutical industry.

FEATURES

- Wide range of feeding tools

- Dependable volumetric feeders

- Highly accurate gravimetric feeders

- Exclusive SFT weighing technology

- State-of-the-art controls Special food-grade and polish finishes available for hygienic applications

PRODUCT RANGE

Single Screw Feeders

Twin Screw Feeders

Rotary Valves

PRODUCT LIST BELOW

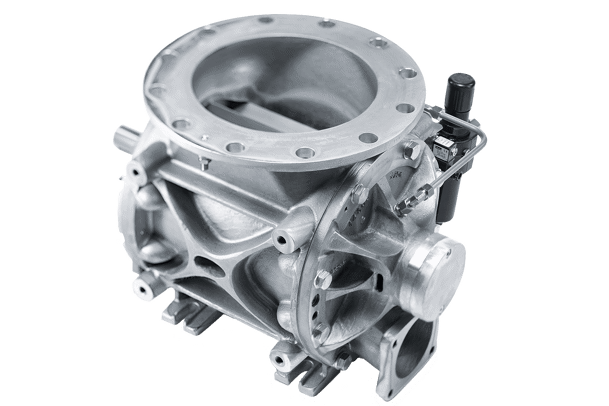

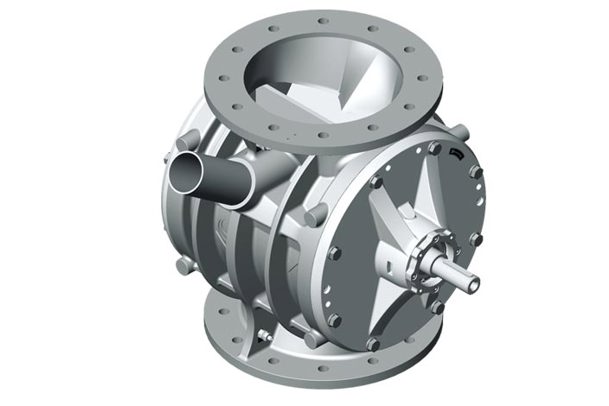

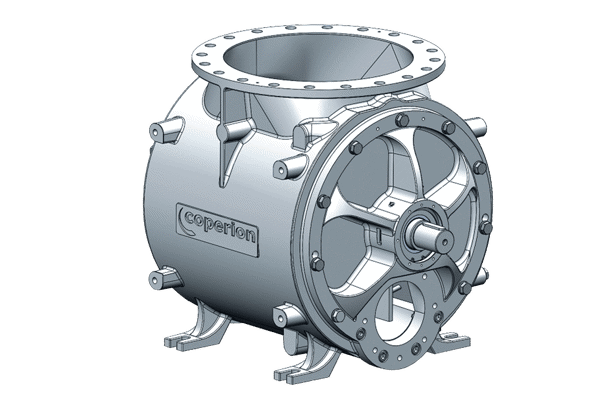

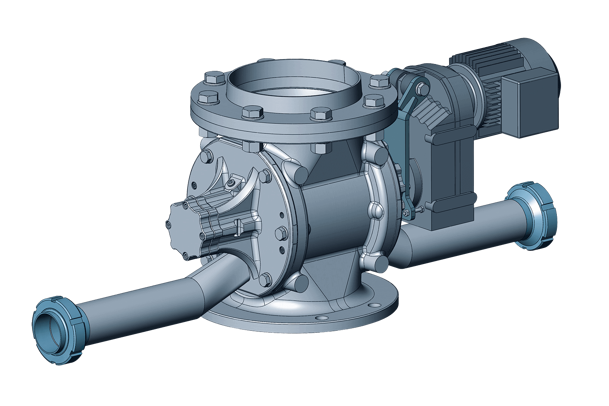

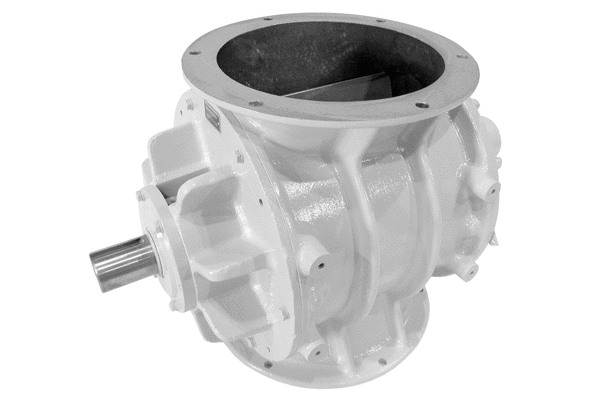

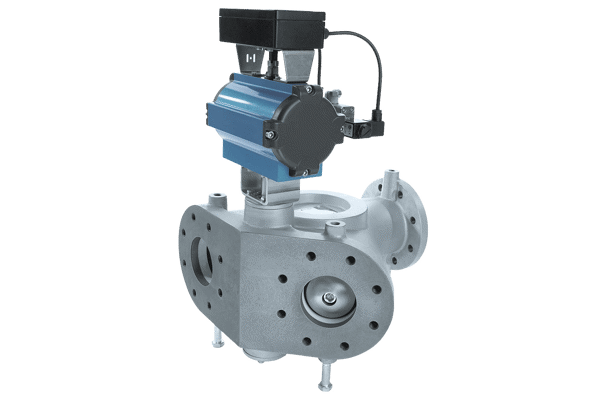

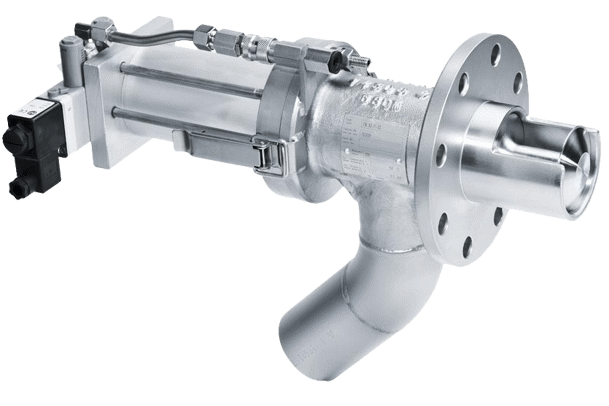

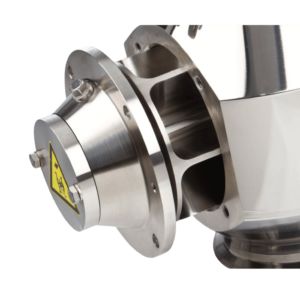

First-class handling for first-class products

Coperion and Coperion K-Tron rotary valves come with the reliability of decades of experience, know-how and proprietary development, and manufacturing with top quality materials.

Our rotary valves are highly regarded as top-quality products in the plastics, chemical, food and minerals industries around the world.

We supply certified solutions for requirements regarding sanitary and flameproof design and ATEX conformity. Our rotary valves also set standards at high pressures and with regard to wear protection.

INDUSTRIES

PLASTICS

Powerful rotary valves to ensure gentle, reliable and economical handling of powders and pellets or granules.

CHEMICALS

Continually optimized rotary valves for a very wide range of requirements that reliably prove their worth and functionality in many bulk materials systems around the world.

FOOD

Innovative technology for optimum operational reliability and sanitary production.

MINERALS

Track-proven wear protection concepts for a long service life.

PRODUCT RANGE

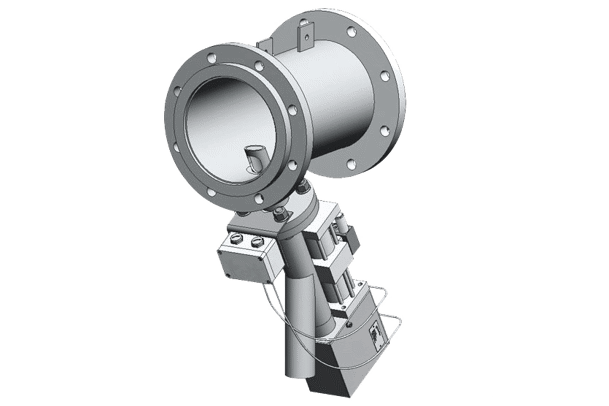

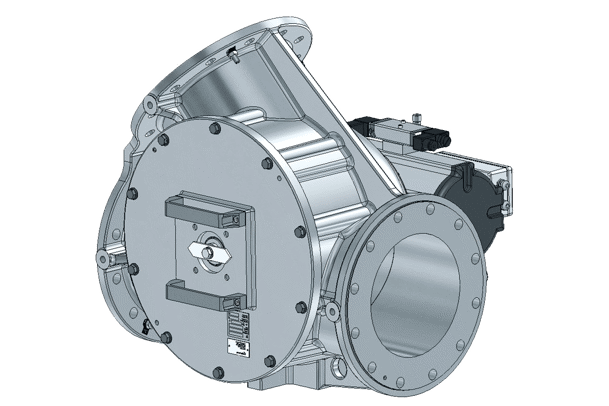

Diverter Valves

PRODUCT LIST BELOW

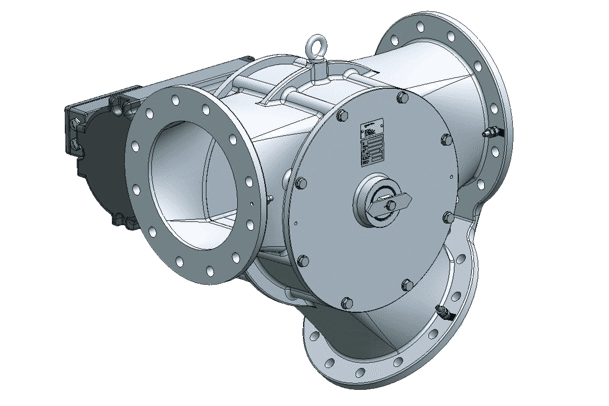

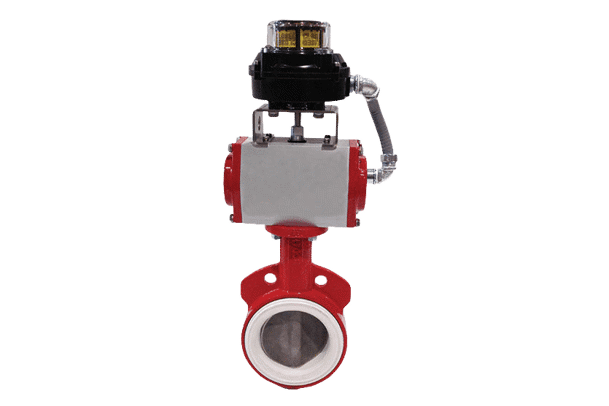

Program overview for diverter valves

Coperion and Coperion K-Tron diverter valves come with the assurance of decades of experience, know-how and proprietary development, and manufacturing with top quality materials.

Diverter Valves direct material from one source to multiple destinations and make sure that conveying air and product are forwarded with low resistance.

We supply certified solutions for requirements regarding sanitary and flameproof design and ATEX conformity.

APPLICATION

- Pressure range up to 6 barg (87 psi)

- Operation temperature up to 100o C [212o F]

- For powders and/or granular products

PRODUCT RANGE

Discharge Valves & Samplers

PRODUCT LIST BELOW

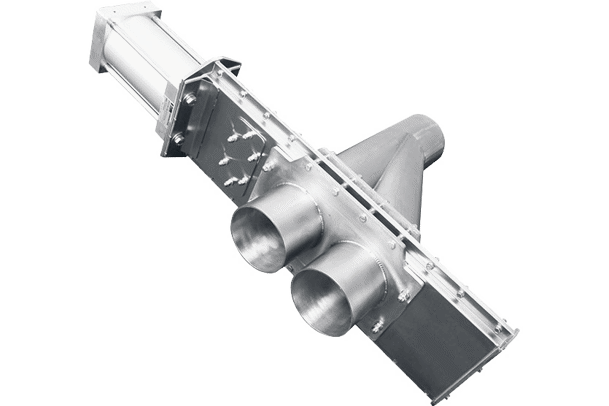

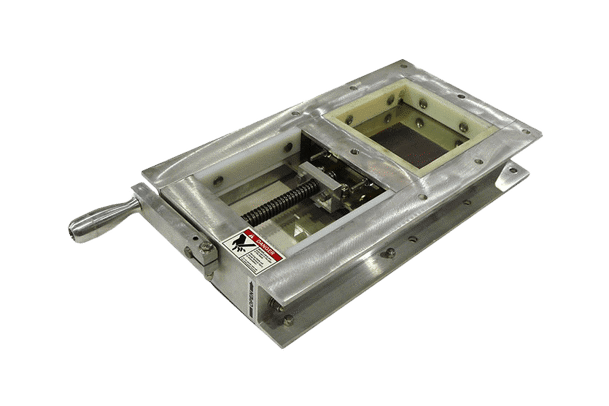

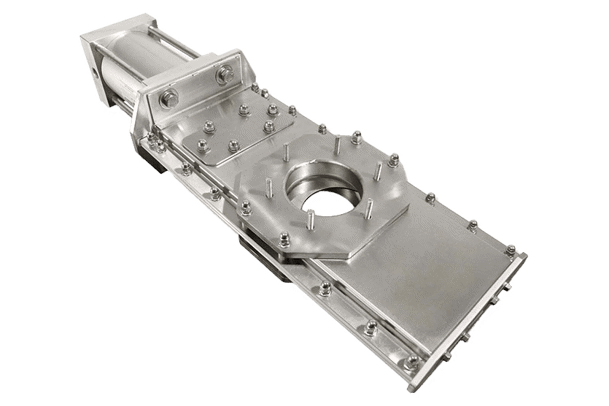

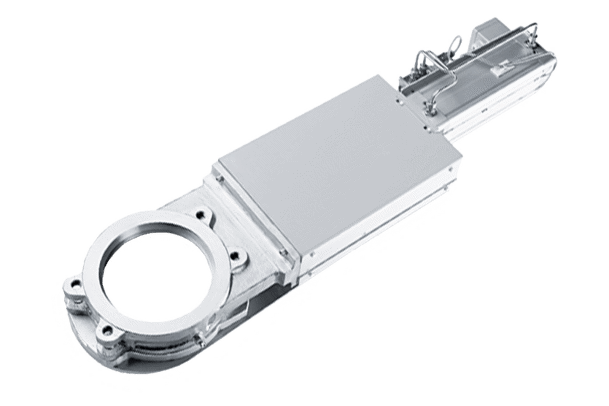

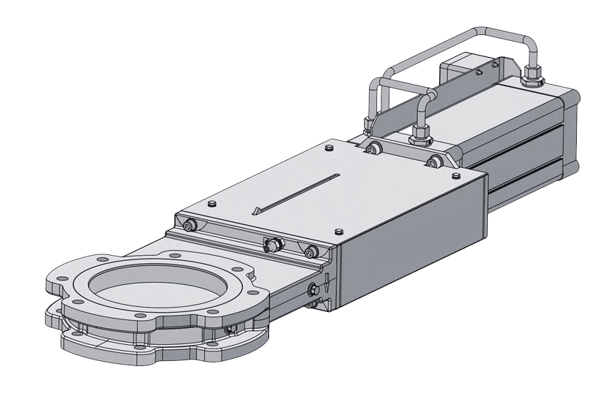

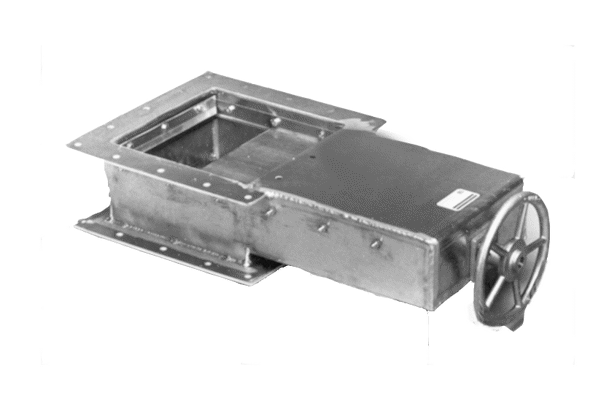

Gates & accessories

Gates are used to control gravity flow discharge from storage bins and hoppers.

Our versatile conveyor units can convey, dry, cool, scalp, screen, quench, dewater, orient, accumulate, separate, distribute, and more. Designed to meet your needs, Carrier conveyors are proven reliable and easy to maintain.

PRODUCT RANGE

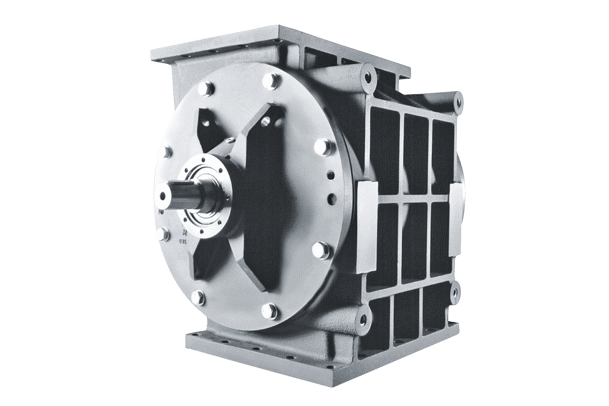

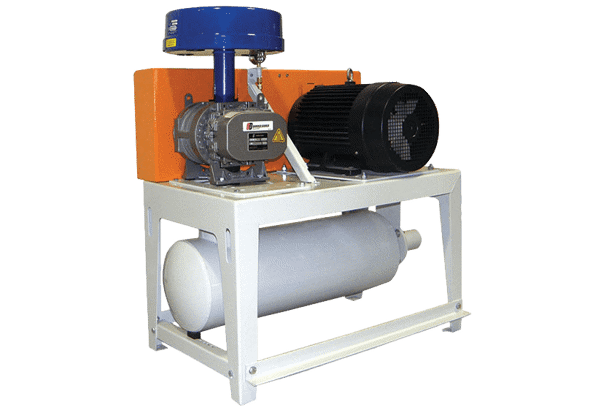

Blower packages

PRODUCT LIST BELOW

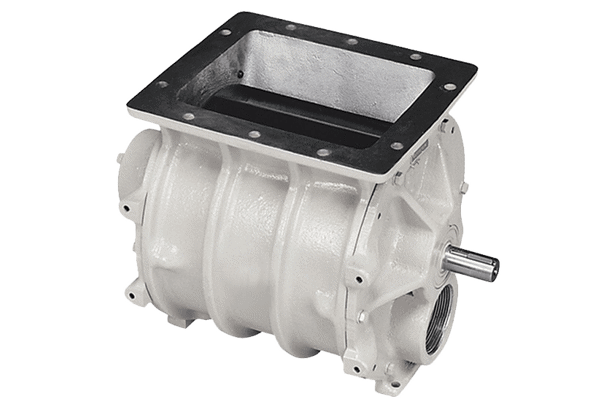

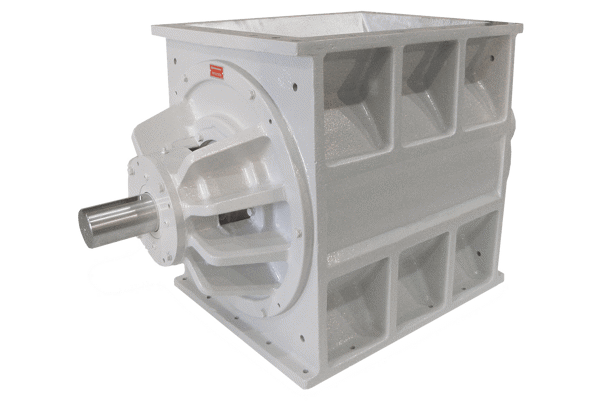

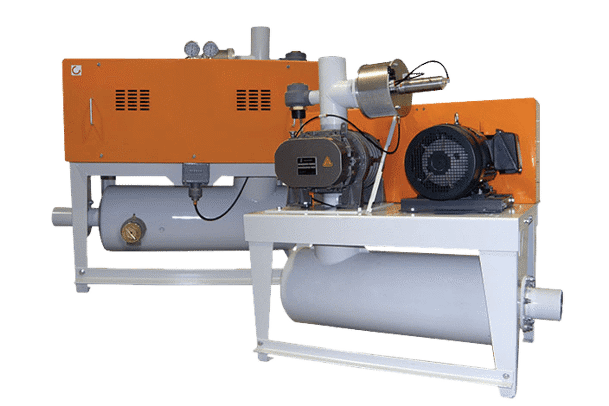

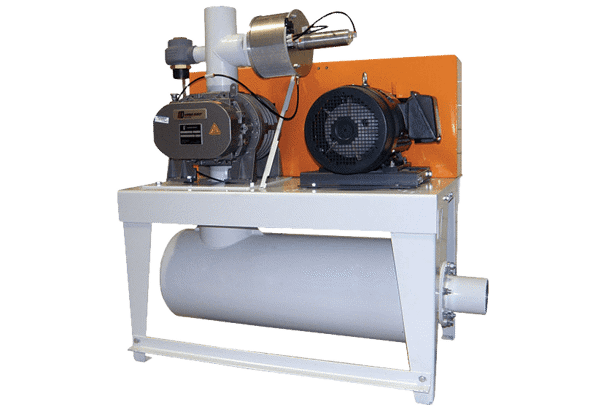

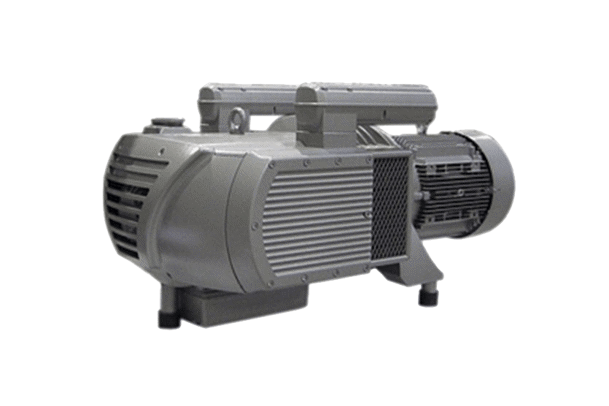

Pneumatic conveying blower packages

Coperion K-Tron supplies a wide range of positive displacement (PD) continuous vacuum, pressure, and vacuum/pressure system blower packages for conveying bulk materials. Packages are available for 2 to 10-inch conveying systems. Each blower package includes a silencer and is supported on a heavy-duty base allowing easy access for cleaning. Built-in braces permit the entire package to be moved into position with a forklift during installation or maintenance.

BENEFITS

-

- Designers carefully calculate the required performance of each blower and how it will respond to your specific application.

- We recognize how important a properly sized blower is for maximum system efficiency.

- Our standard design procedure is to select a blower that will meet the system’s requirements with the blower operating at 85% of capacity. This promotes longer blower life and provides room for field adjustment, if necessary, to fine tune the system.

PRODUCT RANGE

Filters & Separators

PRODUCT LIST BELOW

Separating material-from-air. “Form Follows Function”

Coperion and Coperion K-Tron are industry known when it comes to plant equipment quality. We not only develop plant components for all applications ourselves, we also know all the processes they are used for inside out. Our many years of experience encompass even the smallest detail, and we pass this experience directly on to our customers. This is also true of our filters and separators, designed in accordance with the principle “form follows function”

BENEFITS

- Extensive filtration product range

- Your specification and application dictate the design of our filters

- Consulting and troubleshooting competence for all filtration requirements

- Our experience and references extend back over 60 years of plant engineering

- We are a researching company, develop our own products and subject them to stringent testing in our own test facilities

PRODUCT RANGE

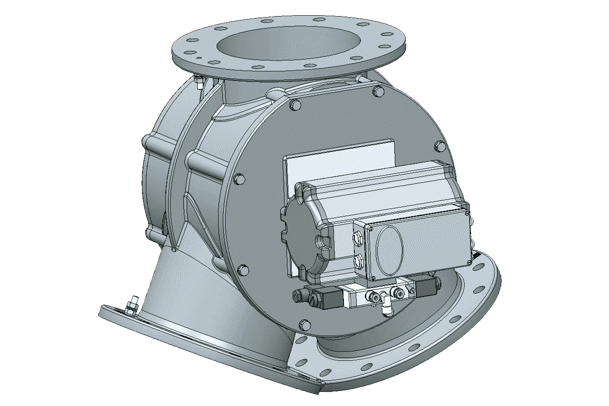

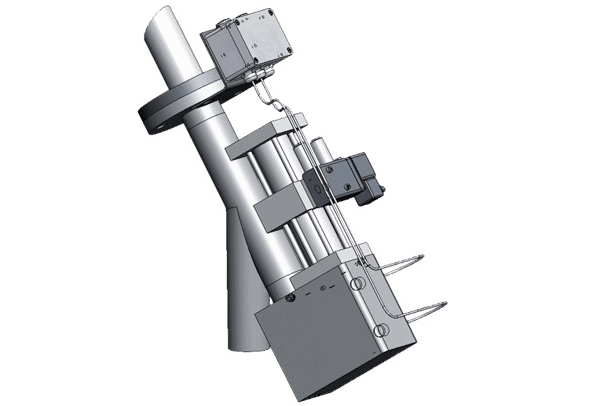

Vacuum Sequencing Receivers

PRODUCT LIST BELOW

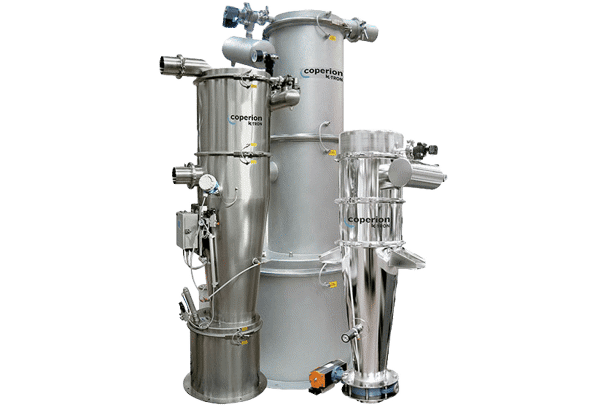

Vacuum sequencing systems for bulk material handling solutions

Finding the right solution for your application is easy with our broad range of receivers Coperion K-Tron vacuum sequencing receivers are designed to high quality standards for pneumatically conveying powders, pellets and granular materials for the bulk material handling industries.

The Series 2400 receivers are designed for a wide range of pneumatic conveying needs. The line offers vacuum receivers for conveying materials in the plastics, chemical, mineral and food industries.

The P-Series receivers are specially designed for sanitary material handling solutions particularly with powders and friable materials in the chemical, food and pharmaceutical industries.

BENEFITS

- Various models available in carbon steel, aluminum (painted) or stainless steel

- All models feature a rugged modular design

- Powder and pellet models available

- Various discharge valve types

- Receivers available with controls suitable for specific needs

- Special food-grade and polish finishes available for hygienic applications

- Models available for all industries of plastics, food / pet food, pharmaceuticals, chemicals, minerals and nonwovens

APPLICATIONS

- Transfer of material received in bags, boxes or containers

- In-plant transfer

- Silo to daybin transfer

- Dilute phase, continuous and batch conveying applications

- Low velocity vacuum dense phase conveying for fragile and premixed materials

- Receivers specialized for direct loss-in-weight feeder refill

- Integrated volumetric feeding and conveying units

- Optimal solutions for most industries

PRODUCT RANGE

Control Systems

PRODUCT LIST BELOW

Feeding, Pneumatic Conveying, and Custom System

Coperion K-Tron provides a variety of control options to meet a client’s process needs. From standard equipment controls to interface options for both the pneumatic conveying systems as well as feeder controls, Coperion K-Tron is dedicated to ensure the client’s specific process control requirements are met.

In addition, Coperion K-Tron’s systems engineering group provides custom PLC based control systems in a variety of control platforms such as Allen Bradley and Siemens.

All automated control systems are developed, designed and manufactured in-house by our highly trained and skilled electrical engineers.

BENEFITS

- More than 60 years of experience and continuous development

- Highly trained electrical engineers with an average of 21 years of industrial automation experience per person

- Products are designed, manufactured and programmed in-house

- Remote diagnosis and configuration

- Standard control packages include many features

- Custom controls designed individually for client’s specific needs

PRODUCT RANGE